Description

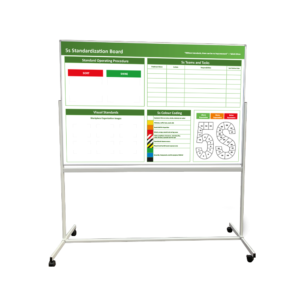

A Mobile Red Tag Station status tracker 90 x 90 cm on lockable wheels

‘Red tagging’ is an effective tool that is employed in the Sort stage of the 5S System. The red tag area is often not against a wall so a mobile version can fit the bill, allowing you to place the board in the Red Tag area itself. Put it in a prominent position as it will encourage the team to see the progress being made. This Red tag station status tracker is printed using dye sublimation onto a mobile whiteboard and provides the opportunity to keep track of 15 ‘red-tagged’ items at a time, driving the process for action. The Red tag Station comes complete with an A4 magnetic see through window to display your company ‘red tag procedure’, a magnetic A4 ring binder attachment for your ‘red tag register’ (which allows you to view your history) and a red tag magnetic holder for your red tag cards.

Product features

- Printed Red Tag station status tracker for effective workplace organization.

- Complete with A4 magnetic paper holder window, an A4 4-ring binder, and a 9 x 12 cm magnetic red tag holder.

- Whiteboard size: 90 x 90 cm.

- Mobile unit with two lockable wheels and fixed whiteboard

- Excellent magnetic steel writing surface.

- Our boards are printed using dye-sublimation printing, with no vinyl overlays making it easy to clean, like a normal whiteboard!

- Dry erasable & accepts magnetic accessories.

- 10-year surface guarantee.

- Delivered with instructions.

- Custom designs and sizes available

- Lead time: 10 working days

Frequently Asked Questions

- What is the Red-tagging board used for?

- The Sort step is the first 5S activity and aims to remove all the unwanted materials from the workplace. After identifying the unwanted materials, they are moved to the Red Tag area and quarantined. The team together then decide on a course of action and that is monitored on the Status Tracker.

- What is the goal of 5s?

- Creating a visual workplace is the goal of 5S. The underlying concept of a visual workplace is to provide simplicity in clear communication to employees to help them carry out their jobs more efficiently.

- When is 5s used in Lean implementation?

- The 5S tool is the starting point for full Lean implementation. Research shows that the 5S tool is a fundamental prerequisite for the implementation of the Lean methodologies and is a primary tool for continuous improvement.

- I like the design but can I amend it slightly?

- Yes! We can make custom 5S boards. Contact Customer Services who will be happy to discuss your project with you. You can also visit our gallery for more design ideas

- Is there a price benefit if I order multiple boards?

- If you order two or more custom printed whiteboards with the same design you will be eligible for a better price. Please contact Customer Services for a quote.

Magiboards USA

Magiboards USA